OEM Services

OEM damper design & development for the powertrains that move the global economy.

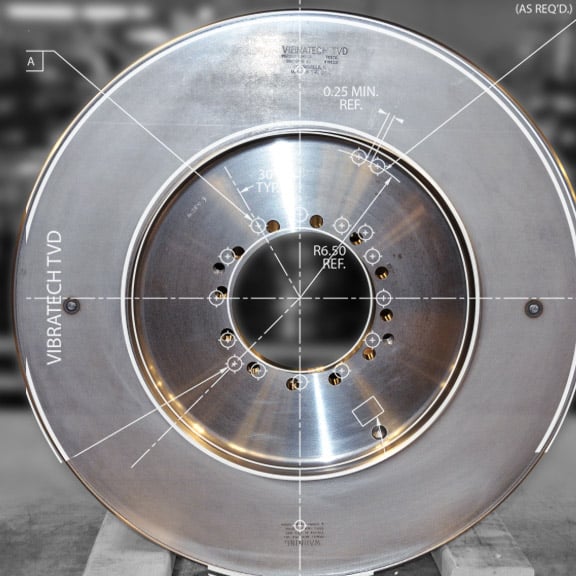

VISCOUS TORSIONAL DAMPER DEVELOPMENT AND MANUFACTURING

At Vibratech TVD our mission is to protect OEM and Tier 1 powertrain systems. We develop and manufacture durable and efficient solutions to torsional vibration challenges. Our viscous torsional dampers are original equipment across diverse applications and industries, and are commonly found in the toughest environments. Manufactured in Springville, New York USA.

- ISO 9001:2015 quality systems.

- ISO 9001:2015 design & development.

- ITAR registered.

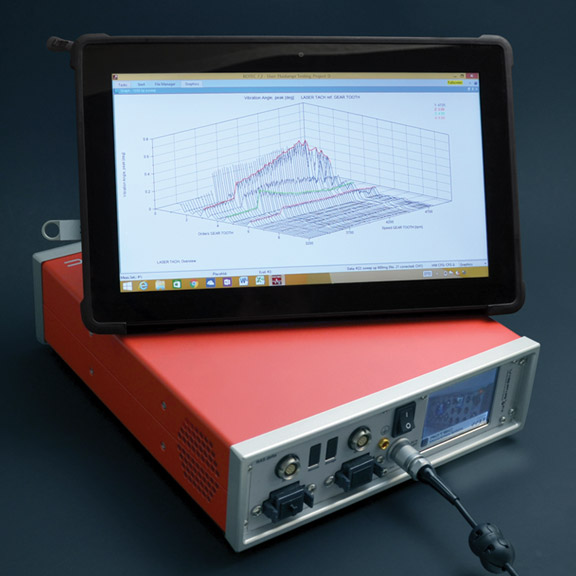

TORSIONAL VIBRATION ANALYSIS

Vibratech TVD is a trusted source for expert torsional vibration analysis. In collaboration with your team, our engineering staff and high quality, professional mobile test equipment can be utilized in several test environments:

- Engine dyno testing.

- Chassis dyno testing.

- On-road, in-vehicle testing.

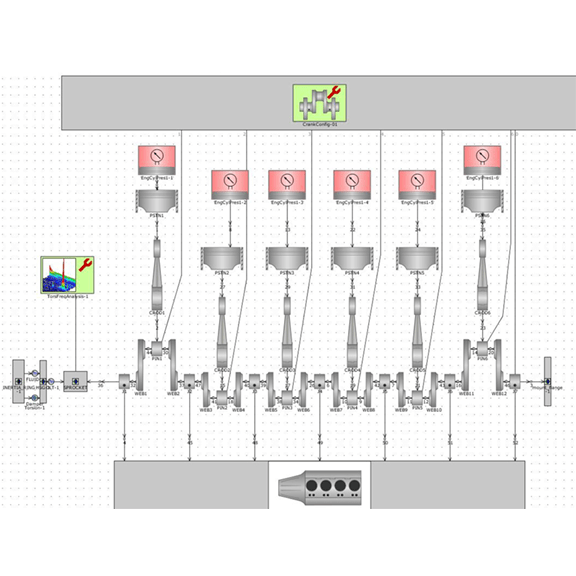

TORSIONAL DAMPER DESIGN MODELING

Early collaboration is the key to long term success. Vibratech TVD offers a variety of custom design options for demanding environments. Knowing the overall goals and objectives of the powertrain team allows us to deliver the best torsional damper within the envelope.

Design variables include:

- Strategic position of mass

- Viscous fluid

- Bearing material selection

- Thermal management

- Component integration

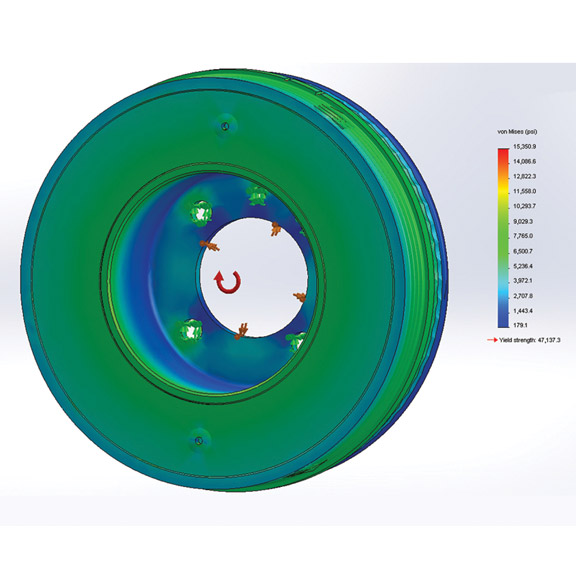

TORSIONAL DAMPER DESIGN TOOLS

Vibratech TVD utilizes an assortment of CAE tools. We are capable of simulating and predicting detailed parameters of torsional damper development requirements.

- Proprietary vibration modeling software stack.

- OEM engineering software compatible.

- CAD and FEA design tools.

- Legacy damping and thermal dynamic formulas for double verification.

Vibratech TVD offers the widest damper application experience in the industry. Our unique 75 year heritage provides the broad knowledge and creativity needed to innovate specific product solutions to exceed with challenges today. – Aaron Neyman, Vibration Solutions Manager

Vibratech TVD’s investment in modeling reduces prototype iterations and increases speed to market. Once a baseline vibration map is created and calibrated through validation testing, then future powertrain configuration changes can be accurately modeled to determine damper performance.

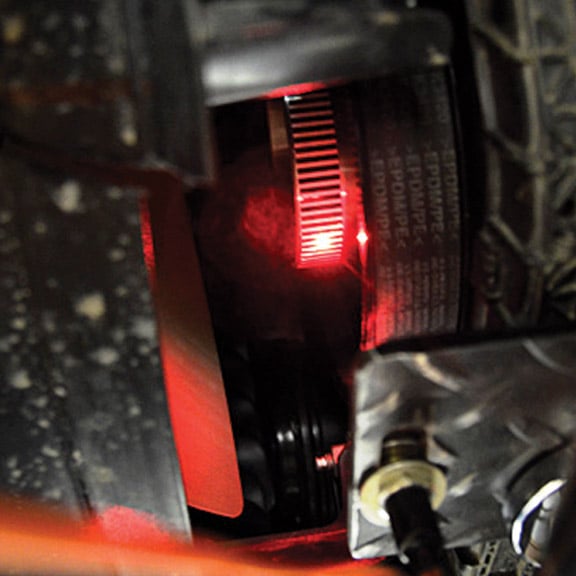

TORSIONAL DAMPER VALIDATION TESTING

Validation testing is performed during torsional damper development. Quality and damper performance criteria benchmarks are established during the collaboration process. These criteria can be validated through a series of tests in different environments:

ON ENGINE

Mobile test equipment with engine or chassis dyno.

OFF ENGINE

In-house lab equipment using log decay methods.

IN VEHICLE

Driveline testing capabilities performed at test track.

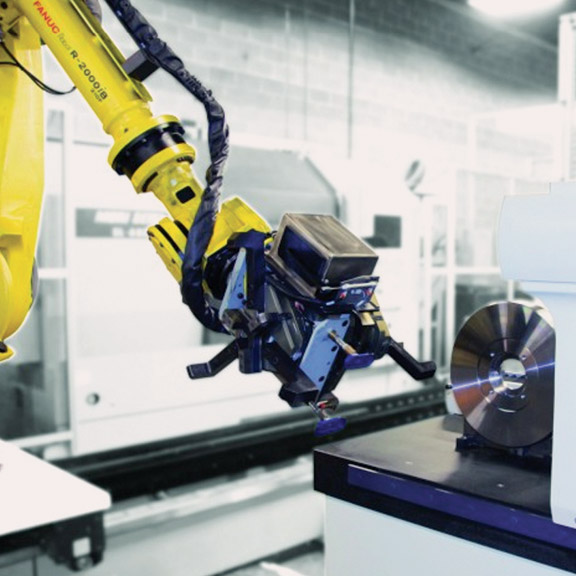

VISCOUS TORSIONAL DAMPER MANUFACTURING

Vibratech TVD manufactures for global customers from our advanced facility located in Springville, New York USA. We offer low-to-high volume production capabilities with certified precision quality. Our multiple long-term domestic material supplier relationships provide for your risk management and supply chain stability.

- Highly skilled and dedicated workforce.

- Robotic automated machining cells.

- Steel and aluminum laser welding.

- Automated assembly line.

- Statistical process control.

- Traceability

- Finished and packaged to customer specifications.

- Inventory management solutions.

Multi-year Partner Level supplier award recipient. - Off-Highway OEM

Multi-year 100% On-Time Delivery / 100% Quality recognition. - Railroad OEM

Vibratech TVD is your long-term torsional damper supplier. Our focus on building relationships, innovative solutions, and continuous operations improvements are the reasons why OEMs repeatedly partner with us.